Graphene Coating

However, Graphene is a carbon-based material that is not really new.

About Us

Graphene Coating

Graphene coatings are considered the newest innovations to emerge in the automobile industry. However, Graphene is a carbon-based material that is not really new. Graphene comprising one layer of carbon atoms, is praised as the sturdiest material known to exist on earth. It is 200 times more rigid than steel and lighter than paper. Two things account for this strength. Today, Graphene is increasingly getting accepted among detailers due to its hardness and ‘anti-static properties. Furthermore, it does not allow the dust to settle down on the surface coated with it because of its anti-static properties.

- Rich & Deep Shine

- Simple DIY Application

- Incredible Hydrophobic

- Ultra-high gloss

Benefits Of Graphene Coating

Graphene coating is a newer and more advanced technology in automotive paint protection that provides several benefits for your car

Anti-static

Graphene enjoys privileges based on its chemical properties. To get a little technical, Graphene is said to be “anti-static,” considering its conductivity properties.

Less Water Spotting

As traditional ceramic coatings are notorious for retaining heat and increasing water spotting, combining them with Graphene makes the top layer of the coating more heat resistant.

Better Hydrophobic

Graphene has a higher contact angle because of its chemical composition and honeycomb structure, making water slide off easier on the surface than the conventional coating.

Longer Durability

Longer durability than ceramic coating: Ceramic coating for cars is sturdy protection, and its longevity has been one of the major reasons for its recognition in the industry.

Ultra-High Gloss

Ultra-high gloss, depth of colour: The nanoparticle Graphene layer leaves an attractively rich, deepened gloss that considerably enhances the shine and appearance of your paint.

UV Protection

Graphene coatings provide protection against scratches, water, UV rays, and chemicals, and enhance the car's appearance.

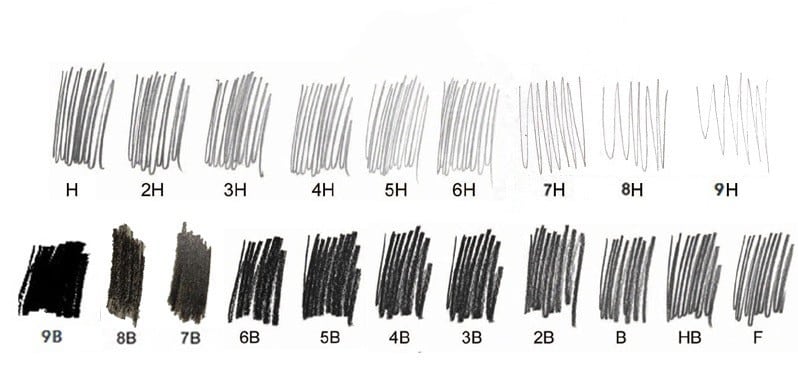

9H & 10H HARDNESS

– Grade Card of Hardness Level

What’s 9H?

The 9H & 10H hardness is now one of the most talked term in ceramic coating to attract the customers not just in India but across the world. But in some matured markets, sellers stopped mentioning about hardness of their ceramic coating because people over there are more educated on this, it may sound funny but it’s the truth. Hence the term “9H hardness” will be continue to be (miss)used until we all get educated.

What’s Mohs?

9H Certificate?

How important is the Hardness?

Almost every quartz/ceramic/glass coatings can reach 9H in the pencil hardness scale. In real life conditions, there are far more important factors than the hardness! The slickness and structural integrity of a coating is the crucial and main factor, that influences the real, every-day experience with a coating. And this is exactly what the famous cigarette lighter test proves, the way it helps in real life is that it can reduce the impact of any scratches.

For Further Enquiries Call

+91 98107 27244

We'll ensure your car stays protected from scratches and chips, be it by dirt, stones, bird droppings, leaves, or bug splatters.

Frequently Asked Questions

A graphene coating is an evolution of ceramic coating technology. Utilizing the latest graphene based technology to make a stronger, more durable coating that is easier to apply. In addition since Graphene is a less reactive ingredient it has been shown that Graphene based coatings are less prone to water spotting or etching compared to ceramic based chemistries.

Ceramic graphene is a material that combines the properties of ceramics and graphene. It is known for its exceptional strength, stiffness, thermal conductivity, chemical resistance, lightweight, electrical conductivity, and wear resistance. Ceramic graphene is suitable for a wide range of applications, including aerospace, electronics, and manufacturing.

Graphene coatings can be expensive, and the application process requires a high degree of precision. Additionally, while ceramic graphene coatings can provide protection against minor scratches and environmental factors, they may not be able to prevent damage caused by larger impacts.

To prepare your car’s surface for ceramic graphene coating, you should thoroughly wash and dry the car, remove any surface contaminants, and clay bar the surface to remove any embedded dirt or grime

Yes, Graphene is a wonder material that the car care industry finally has access to. The physical properties allow this coating to outperform any other coatings on the market. Being extremely easy to apply and maintain, Graphene Matrix is extremely cost-effective and gives you the most value out of any other coating.

Ceramic graphene coating can be beneficial for protecting a car’s exterior, offering durability, hydrophobic properties, chemical resistance, easy maintenance, and a glossy finish. However, it can be expensive and require precise application. Ceramic graphene coatings can protect against minor scratches and environmental factors, but they may not be able to prevent damage caused by larger impacts.